Channel sizes in Australia follow standardised dimensions so builders, fabricators and engineers can select the right structural steel member for load-bearing frames, floors, roofs and commercial or industrial projects. The most commonly used channels are Parallel Flange Channels (PFC), offered in standard lengths and manufactured to AS/NZS 3679.1.

This guide breaks down key channel sizes, how they compare with universal beams and columns, and how Midway Metals supplies these products for real-world structural applications.

Why People Search for Channel Sizes

From our experience supplying stainless structural profiles to commercial construction, mining and infrastructure projects, searches for channel sizes usually fall into one of three intents:

- Design-stage planning: Engineers confirming the correct PFC size, weight and cross-section for load calculations and modelling.

- Procurement and fabrication: Builders checking availability, standard lengths and fabrication options before placing an order.

- Replacement or maintenance: Facility teams and fabricators sourcing like-for-like channels for upgrades or repairs.

Understanding Channel Sizes (PFC) in Australian Construction

Parallel Flange Channels are defined by:

- Depth (D)

- Flange width (B)

- Web thickness (T)

- Mass per metre (kg/m)

Their open-side design makes them highly effective in wall framing, lintels, machine bases, skids, and secondary structural support.

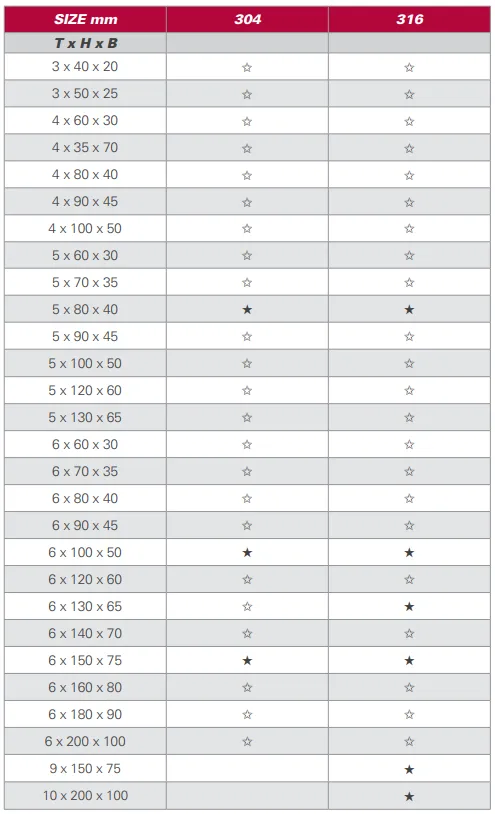

Stainless Steel Channel Sizes (304 & 316)

From the Midway Metals Products & Services Catalogue

How Channels Compare to Other Structural Steel Forms

Channels vs Universal Beams (UB / I-Beams)

Universal beams (often grouped with I-beam sizes) offer higher strength around both axes due to their symmetrical flanges. Channels, by contrast, provide strength in a single direction and are often selected where the vertical middle section (web) must be integrated into a frame or wall.

Channels excel in:

- Lintels and edge beams

- Wall studs and uprights

- Platforms, skids and conveyor frameworks

UBs excel in:

- Primary load-bearing beams

- Portal frames

Channels vs Universal Columns (UC)

Universal columns offer superior load capacity due to their near-equal web and flange dimensions. Channels are chosen when:

- A lighter member is needed

- Only one-directional load support is required

- Integration with existing frames demands an open or flush side

Many commercial builders specify UCs for heavy vertical loads and channels for bracing, secondary beams, and frame components.

Choosing the Right Channel Size for Your Project

Structural Requirements

Engineers assess load capacity, deflection limits, and section modulus before selecting a channel.

Grade (304 vs 316)

Choosing the right stainless steel grade is essential. 304 suits general construction; 316 is essential in marine, food-grade, chemical, and corrosive environments.

Read our article for help Decoding Grades.

How to Estimate Weight When Selecting Channel Sizes

Mass per metre matters for:

- load and deflection calculations

- cranage and lifting plans

- transport optimisation

- quoting and take-offs

Midway Metals provides accurate engineering weights for stainless channels, but the following general table helps during early design, even before final grade selection.

General Channel Weight Table (kg/m)

Use this table for preliminary load estimates before committing to final specifications.

Compliance, Tolerances & Meeting Structural Requirements

Channel selection must also consider compliance with ASTM A276/A484M for stainless profiles.

1. Dimensional tolerances

The standard governs:

- flange width accuracy

- web thickness variation

- overall straightness

- mass tolerance

These tolerances are critical when channels must align with drilled plates, gussets, or bolted assemblies.

2. Load performance

Engineers rely on:

- kg/m tables

- material yield strength

- section modulus

to verify whether a channel meets structural design requirements.

Where Channels Fit in Real Projects

Drawing from recent Midway Metals projects and supply work:

Commercial construction

Channels are used in façade framing, awnings, and mezzanines where a lighter but strong member is required.

Mining & processing

PFCs form the skeleton of platforms, walkways and conveyor systems—areas requiring corrosion-resistant stainless steel.

Industrial fabrication

Fabricators favour channels for skids, machinery bases and modular frames due to their ease of welding and consistent load characteristics.

Why Midway Metals for Stainless Channels

As Australia’s largest independent stainless steel stockist, Midway Metals provides:

- consistent national availability

- guidance on grade selection and applications

- rapid response for urgent or breakdown work

Standard Lengths, Availability & Ordering

We stock a wide range of stainless channels in standard 6 metre lengths, with custom cutting available for project-specific requirements. We also supply project-ready batches for commercial builders and fabricators needing reliable, staged deliveries. Our team coordinates supply Australia-wide to support tight construction and maintenance schedules.

Get Help from the Steel Experts

If you’re modelling loads, planning fabrication or sourcing stainless channels for a commercial or industrial project, our team can help confirm the right section, grade and requirements.

Explore our full range of stainless steel products or speak with our specialists for guidance on selecting and preparing channel profiles for your next build.

FAQs

What are the most commonly used channel sizes in Australian construction?

The most frequently specified PFC sizes are 100 x 50, 125 x 65, 150 x 75, 180 x 75 and 200 x 75, depending on load requirements and structural applications.

Are stainless steel channels stronger than carbon steel?

Strength is determined by grade, but stainless channels provide superior corrosion resistance, often critical in industrial, coastal or chemical environments.